In this post I show you exactly how to use a screw extractor set to remove a broken head bolt from an engine. I made a step-by-step video to show you exactly how you can use an easy out to remove a fastener on which the head has snapped off. You can watch the video embedded below.

Here are the steps required to use a screw extractor set:

- Make a flat surface in the middle of the snapped portion using a hand file, angle grinder, dremel tool or similar

- Mark the centre with an engineers scriber

- Pick up the mark you just made with a centre punch. Hold the centre punch in position and hit once with a hammer.

- Using a small diameter drill, drill down into the broken fastener, being careful to stay centred and going deep enough to avoid the screw extractor bottoming out in the hole (The size of screw extractor to use depends on the size of the fastener, and the estimated torque required to break it free. The larger you go the less likely it is that you will snap the screw extractor when you apply torque. If you have chosen a larger diameter screw extractor then start off using a small drill bit and then progressively open out the pilot hole you made until you have appropriately sized hole.)

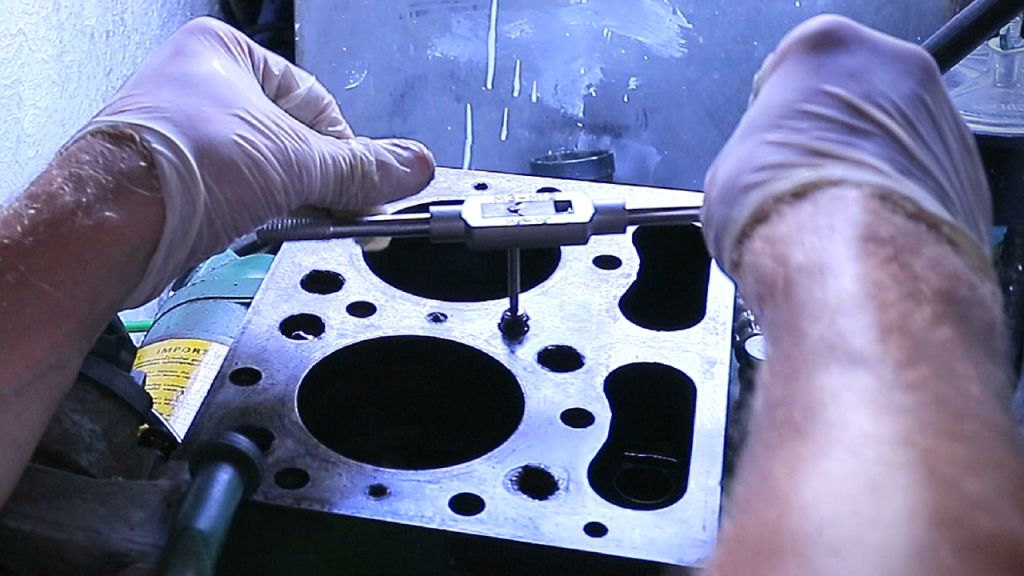

- Place the screw extractor in the hole, and hit it once with a hammer

- Apply torque in an anti-clockwise direction. The screw extractor will attempt to thread itself into the hole and a huge amount of friction is generated between the screw extractor and the broken fastener. It is best to apply torque evenly, and the kind of handle that you would find in a tap and die set is ideal

- Once the torque applied exceeds the breakaway torque of the fastener, the fastener will rotate and unscrew

The backstory behind this post and my video is this: I was working on an engine and after completing the work the time came for me to refit the cylinder head to the engine block. I had already done this once before, so I wasn’t too concerned about the job. Unfortunately, I chose to use a very cheap torque wrench to tighten the head bolts up to the required 70 N m. The torque wrench failed to ‘break’ at the desired torque, and as a result one of the head bolts snapped in between the cylinder head and the engine block. So off the cylinder head came again (oh what fun!).

I have been using screw extractor sets for many years after first learning about them during my apprenticeship as a mechanical technician in the Royal Air Force, where I served as a technician on aircraft for 7.5 years. When used correctly they are simple and effective. I once used an easy out kit to remove a snapped bolt on the undercarriage of a Chinook Helicopter, 300 miles North of the Arctic Circle (This was nothing to do with me over-tightening the bolt this time[!] it was the -25 degrees Celcius temperatures which were placing every component under stress and equipment failures were common.)

Here is my video taking you through how to use a screw extractor step-by-step:

So, as expected, I was able to successfully and easily remove the broken bolt with the screw extractor set. Every situation is different and the bolt in my video wasn’t a particularly challenging example, as it had snapped off as a result of tension, rather than excessive friction between the fastener and the threaded receiver in the engine block. Removing a bolt which has rusted in place for 30 years requires a lot more torque, but the larger easy outs can provide this.

There are many other tricks which can be applied to remove snapped bolts and other fasteners, but without knowing the exact circumstances I can’t cover all bases. Here are some further generic tips which may be helpful:

Hit stuck fasteners with a hammer. (The shock can help to release them)

Penetrating oil is your friend. (Spray lots on and give it time to work)

Use heat OR cold. (You can often help loosen seized components by heating them with a propane torch. The different parts will have very slightly different rates of thermal expansion and the difference between the two can be enough to break them free from each other. Another technique is to use a can of air duster, held UPSIDE DOWN, which sprays out a jet of super-cooling liquid, which can achieve the same results as heat using the power of cold. Be careful as you can give yourself frostbite doing this. Yes, really!)

Use a large screw extractor (Where lots of torque is required, use the largest screw extractor you can use without damaging the threads around the broken fastener. This will give you more torque to break the fastener free)

Here are some affiliate links to the most critical tools used for this job:

Screw Extractor Set ⯈ https://amzn.to/2PkVvPv

Cobalt Drill Bits ⯈ https://amzn.to/2vYcWx7

Engineer’s Scriber ⯈ https://amzn.to/2PmNLwg

Centre (Center) Punch ⯈ https://amzn.to/2Po6TKj

I hope you found this post and my video useful. If so, feel free to throw a coin in the tip jar. 🙂

Alternatively, you can say thanks and help me provide for my family without spending a penny, by sharing this post or my video on social media. That really helps me grow my audience and I really appreciate your help.

Cheers!

Chris 👍

Leave a Reply